As data center technology evolves and the industry grows, efficient airflow and energy management practices have become more important than ever. Uncontrolled hotspots and excessive mixing of hot and cold air within your networking environment could mean higher energy costs for you, or worse, catastrophic equipment failure. AZE's hot and cold aisle containment systems are your solution. They separate cold air being supplied to your equipment from hot equipment exhaust air and enable greater cooling efficiency from data center air conditioning units. Lower your energy expenditure and gain the peace of mind that your equipment is operating at the right temperature consistently.

The amount of energy used to maintain acceptable temperatures in the data center can be greatly reduced by containment. Data center containment is the separation of cold supply airflow from hot air coming out of equipment exhaust. By separating the air, you are able to save revenue by reducing your energy consumption, and improve overall equipment performance and efficiency. Data center containment has virtually changed the way IT facilities are designed and operated by fully separating cold supply from hot equipment exhaust air.There are serveral common containment solutions used in the data center for engery saving.

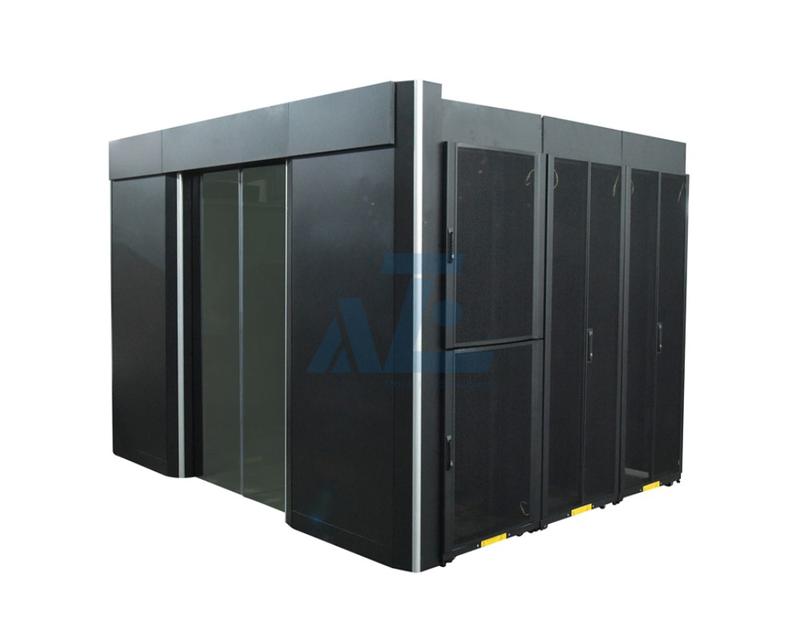

- Cold Aisle Containment

Enclose a cold aisle with ceiling panels above the aisle, between adjoining racks, and with doors at the end of the aisle. The Cold Aisle Containment (CAC) approach encloses the cold aisle with ceiling panels above the aisle between adjoining racks and with doors at the end of the aisle. This allows the cold air from the perforated floor tiles in front of the cabinets to be contained and delivered to the server equipment air inlets.

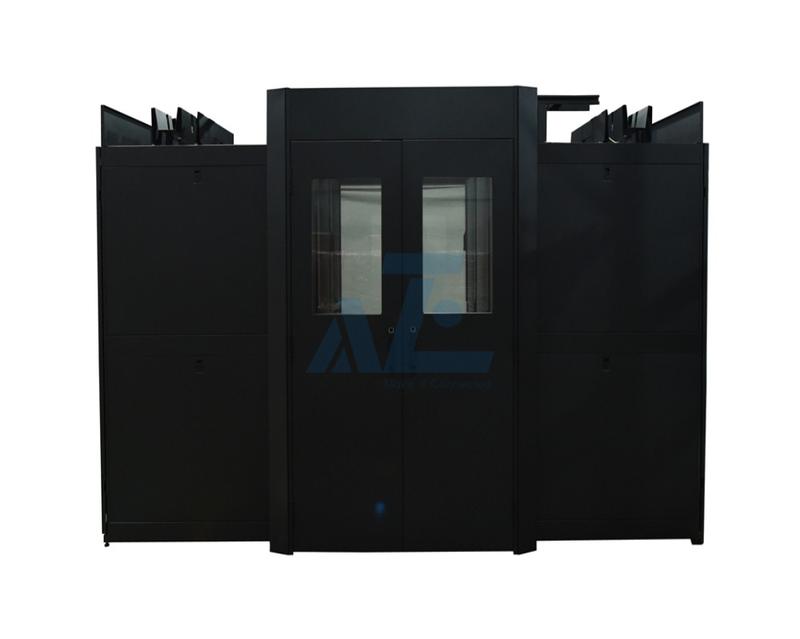

- Hot Aisle Containment

Keep hot exhaust air, emitted from server racks, separated from the cold air.In its simplest form, Hot Aisle Containment (HAC) consists of a barrier that guides hot aisle exhaust airflow upward back to the CRAC (computer room air conditioner) return. This method keeps hot exhaust air emitted from server racks separated

- Chimney Systems

Push hot air through the chimney up to the ceiling return air plenum.A chimney system consists of a solid metal chimney that extends from the top rear of the IT racks. The hot air is pushed through the chimney up to the ceiling return air plenum. This type of system is highly compatible with most data centers due to the fact that it can be installed on an already existing enclosure. They can be installed not only on an individual cabinet but also on a system which can span several cabinets.

Aisle containment is a layout design for server racks and other computing equipment in a data center. The goal of a hot or cold aisle configuration is to conserve energy and lower cooling costs by managing air flow.Designing the proper containment system requires lining server racks in rows (or aisles) with the cold air intakes facing one direction and hot air exhaust facing the other. This makes one side of the row hot and the other side cold.

The system is built around an CRAC (Computer room air conditioning unit) AC unit. The cold air intake side of the row faces the CRAC output ducts.This is the cold aisle. The hot aisle is where the hot side of the row typically pours into the CRAC intake. Cooling capacity will increase. Keeping these aisles separated from one another is the core of containment.

Proper aisle containment creates a physical barrier that separates the hot and cold air from mixing. Containment panels or strips create a partition to isolate either the server supply air (cold aisle) or the exhaust air (hot aisle). Preventing the supply and exhaust air from mixing significantly increases the capacity and cooling efficiency of the cooling infrastructure.

Hot Aisle & Cold Aisle Containment: Which one is best for us and our situation?

The short answer is: Each location varies! Certain factors will dictate whether you isolate the hot aisle for the cold aisle.

Hot Aisle

A Hot Aisle Containment System (HACS) encloses the hot aisle, allowing the rest of the data center to become a large cold-air supply into the servers and floor power equipment.

It's best that we sit back and talk with you to best understand what you have in place and review your needs. Between the two, for new build type of situations, we're seeing a hot aisle containment is the most chosen for raised floor Data Centers. Hot aisle containment in short consists of a physical barrier that guides hot exhaust airflow back to the AC return and uses natural process of "warm air rising" to help efficiency. The higher the heat back to the AC coils, the greater the efficiency by adjusting temperature (RH set points and lower AC fan speeds).

Another advantage of hot aisle containment is the thermal override. This is when the surrounding cold aisle areas (typically larger in square footage), act as insulation, keeping the entire data center more stable until power or cooling is restored.

Cold Aisle

A Cold Aisle Containment System (CACS) encloses the cold air in the aisle, allowing the rest of the data center to become a large hot-air return plenum.

One type of containment consists of a physical barrier that allows the supply air to pool inside the cold aisle. This“lid”ensures a uniform and predictable air temperature at the server in-take.

Note: if the data center is cold aisle contained, consideration for room cooling of any 3-phase UPSs and floor PDUs is needed.

We see a lot of cold aisle (lid) contained project for in-row cooling project on slab floor.

For Legacy data centers, again, it really does depend on your existing infrastructure and we see both HAC and CAC containment. There can be some difficulties with the installation with existing overhead racks, and sometimes the servers aren’t positioned in the best hot aisle and cold aisle containment configuration. So there are a lot of different little variables with an existing legacy data center that weren't intended to become data centers but now are but none the less will benefit with some containment.

The energy savings, we are seeing, can be up to 30% higher if we completely contain either the cold or hot aisle to eliminate airflow mixing. This will also ensure your racked equipment will run longer, if it stays cooler.

Remember to also blank those empty rack U’s with blanking panels and include any gaps in between cabinets. These are notorious for hot air wrap around and inefficiency. Blanking panels are a great low cost way to see immediate improvements.

Stay cool!