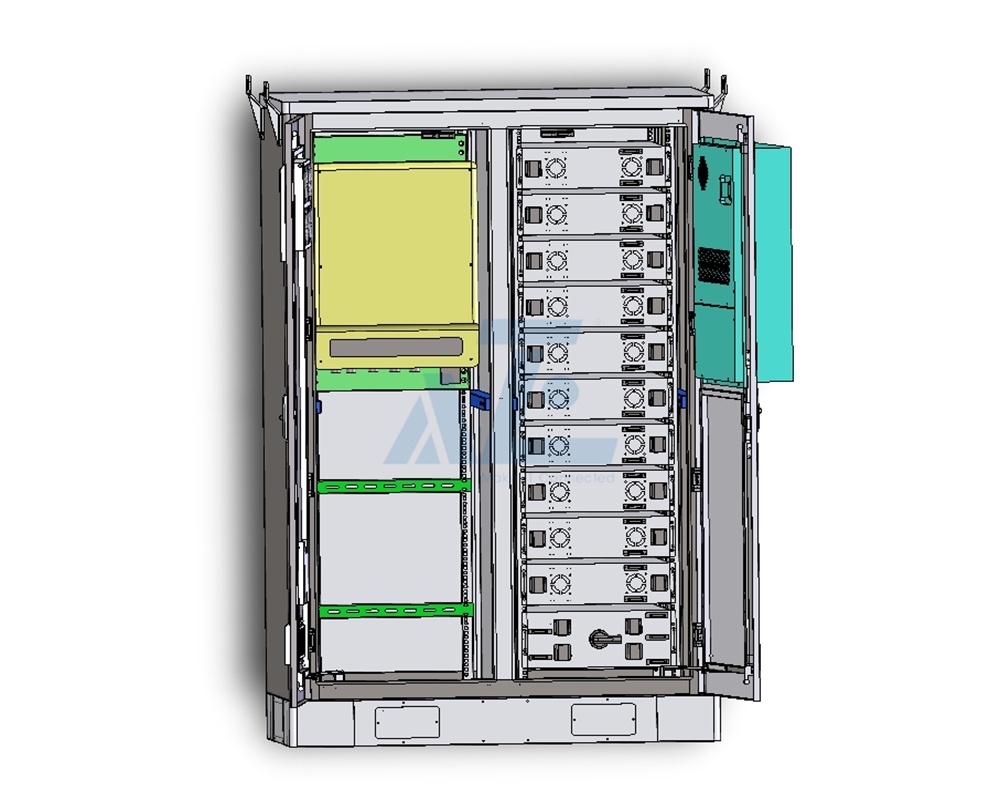

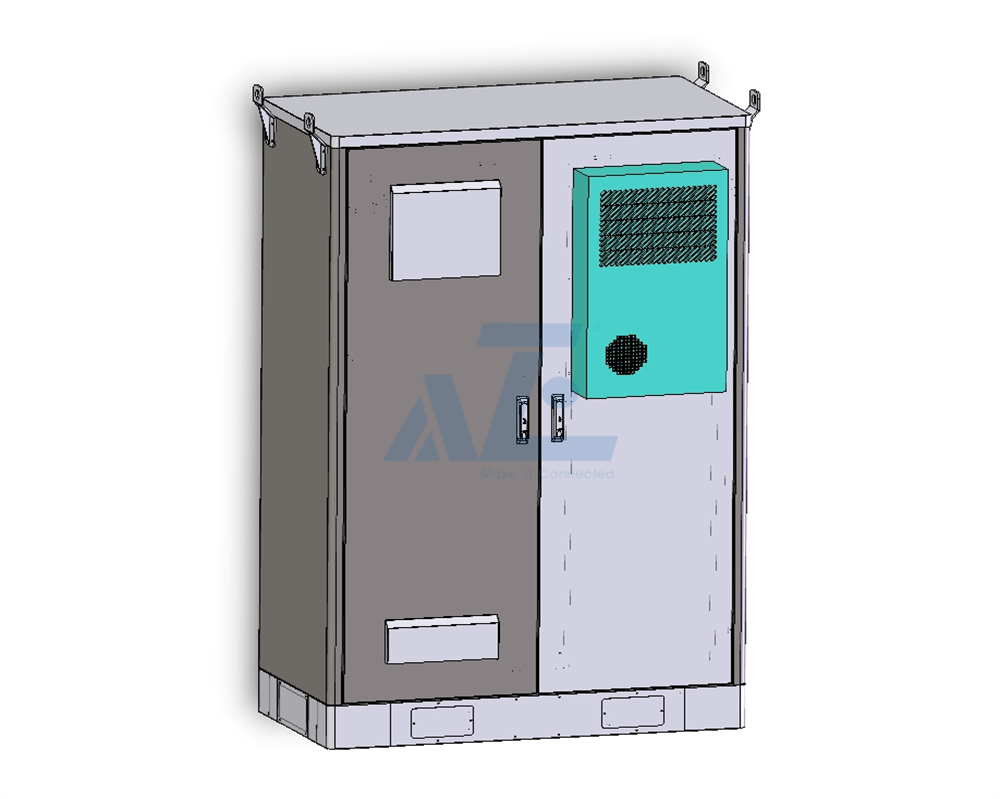

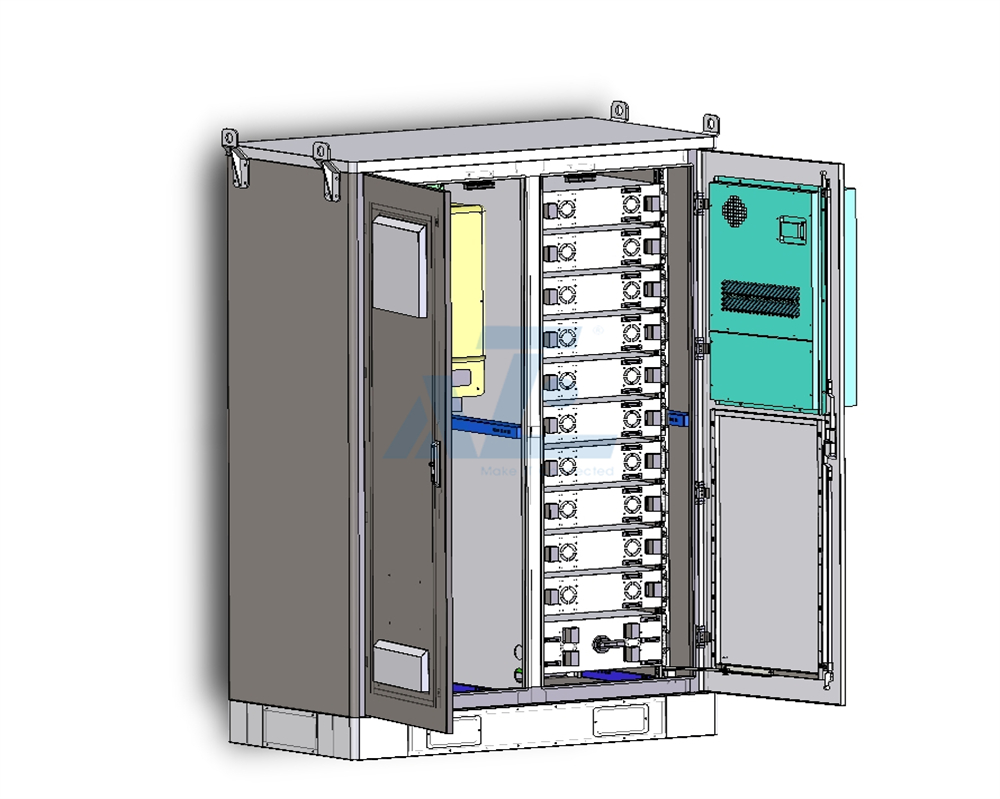

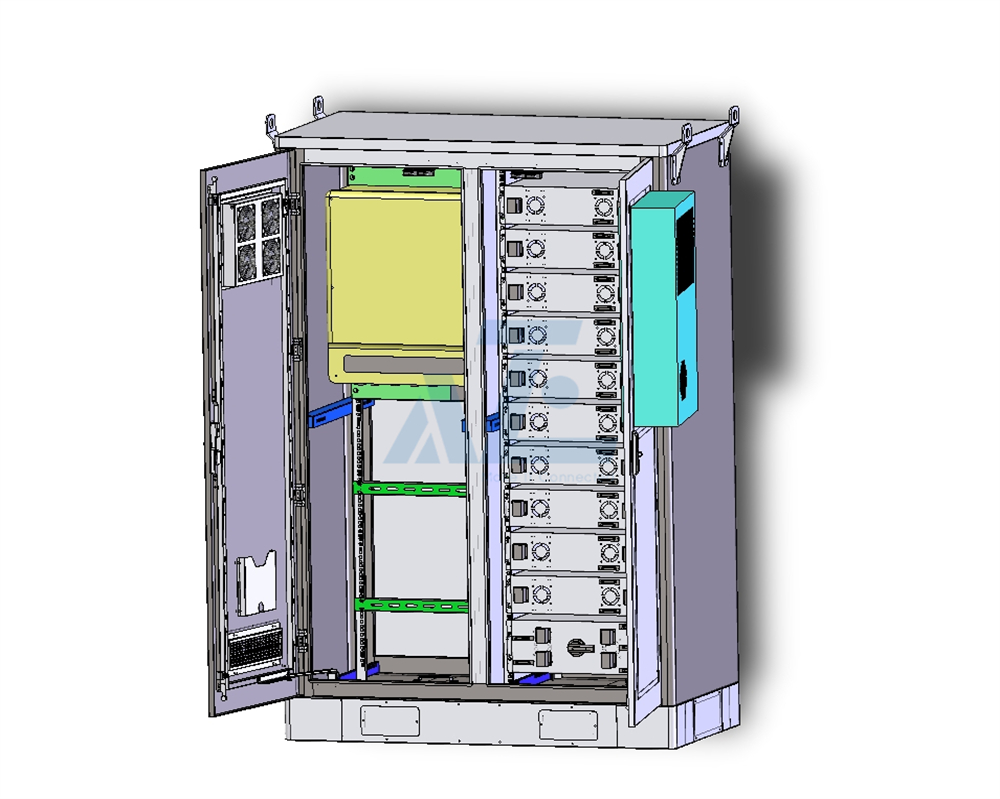

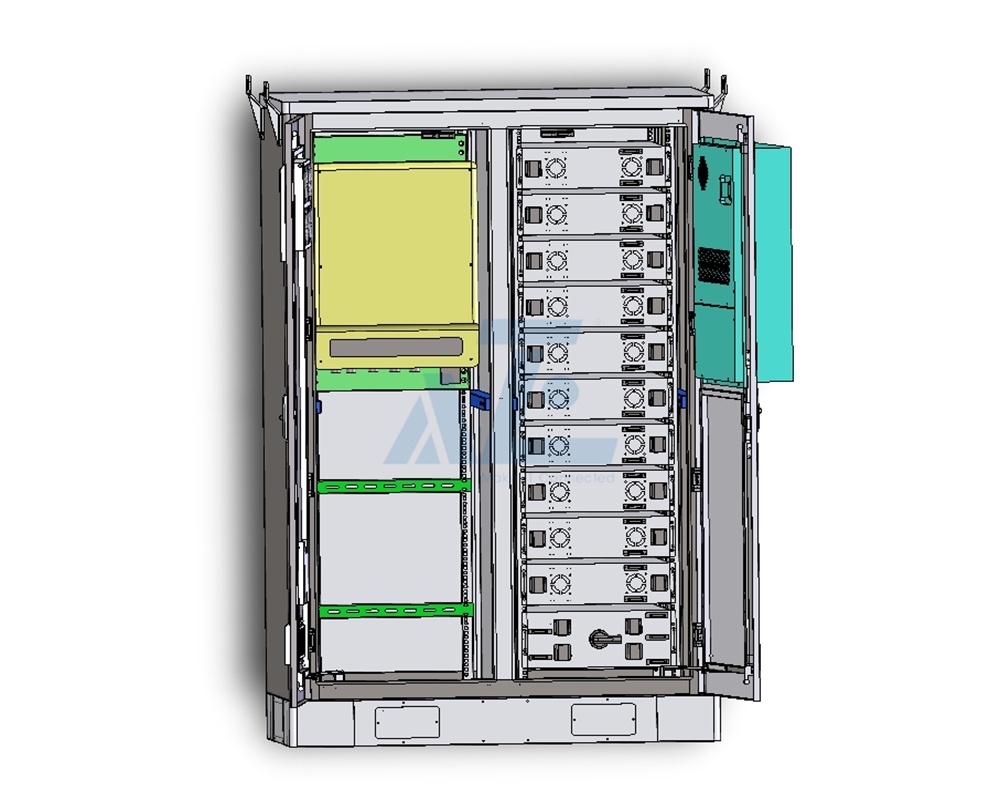

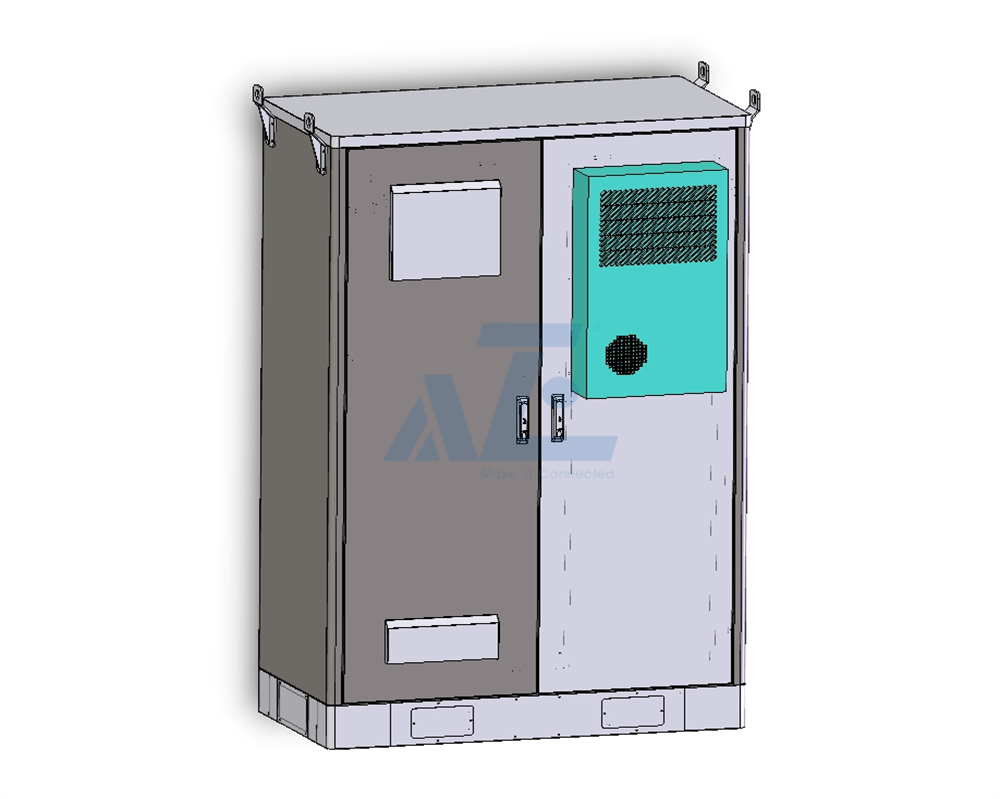

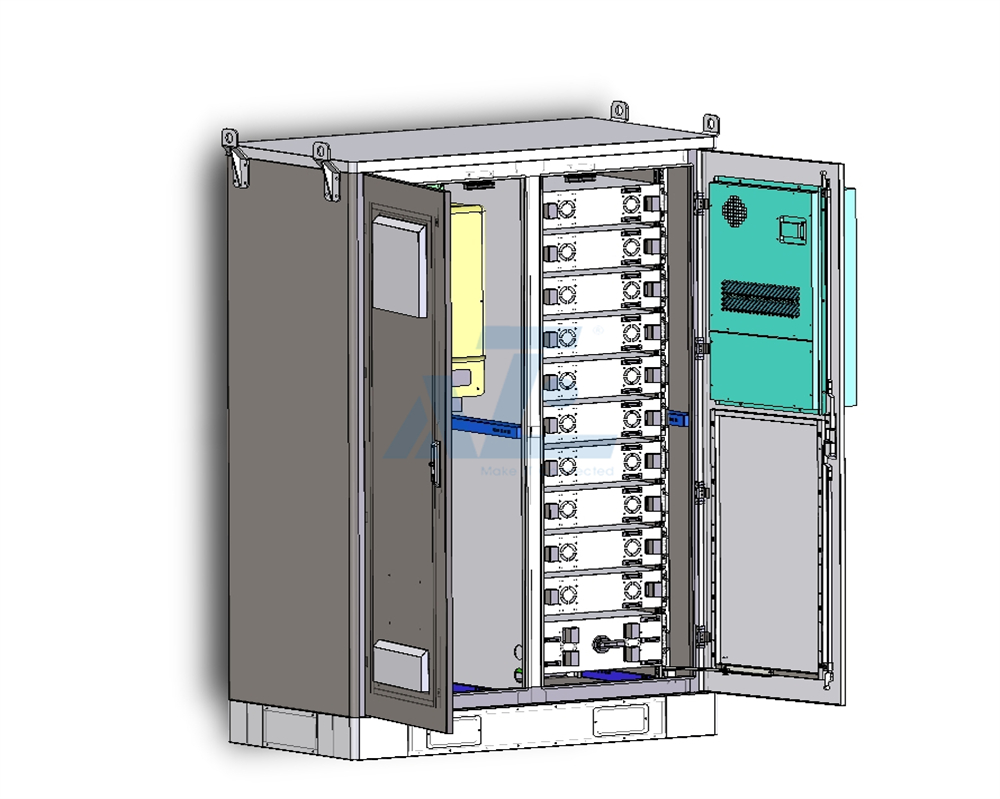

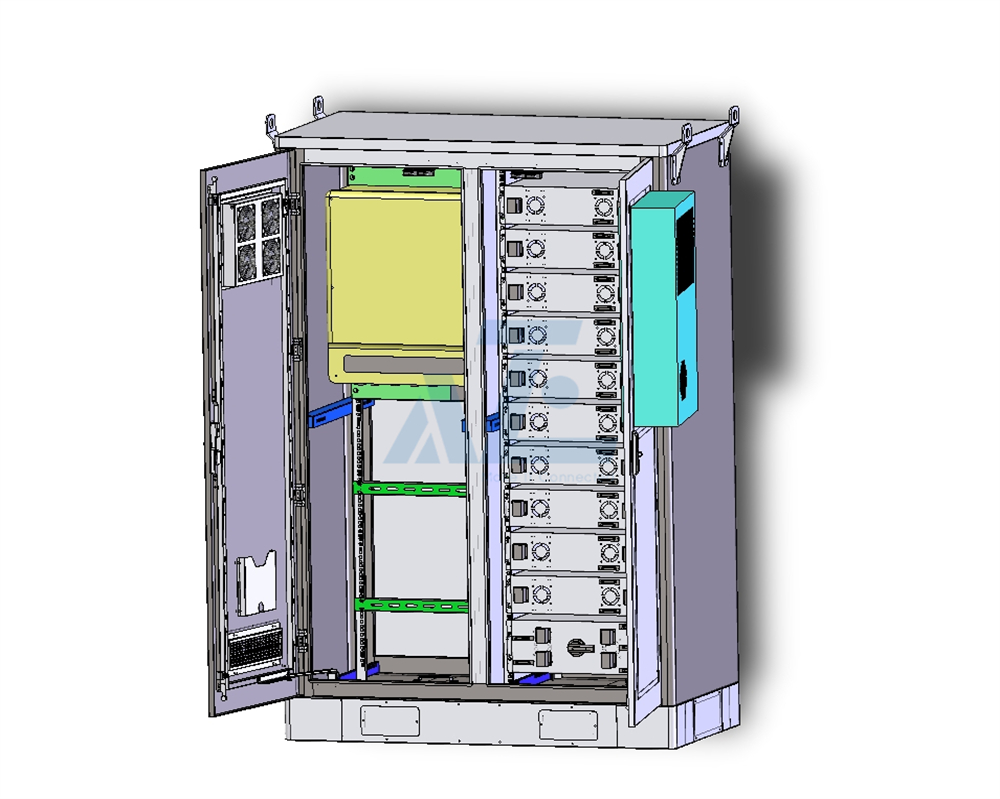

50KW 100KW 150KW 215KW Air-cooled C&I BESS Energy Storage Cabinet

Model:RODF421375DC1K5W-B10

AZE's Our air-cooled C&I BESS Energy Storage Cabinet is the perfect solution for your business. With advanced air-cooling technology, scalable design, and smart energy management, our system delivers reliable performance, cost savings, and peace of mind. Whether you're integrating renewables, reducing demand charges, or preparing for grid outages, our BESS cabinet is your partner in energy resilience and efficiency

-

19" Rack mounts with slide-in shelves for battery module mounting

-

Battery module capacities ranging from 2 -12 modules

-

Universal racking system for multiple battery brands such as Pylontech US3000C and US5000B

-

Fully welded construction, stainless steel bolts and fittings installed throughout

-

Double front doors with segregation between battery section and equipment section

-

Robust 3-point locking system

-

Gland plates fitted internally

-

Rain protected vents on either side and on top to facilitate passive ventilation. These covers are removable

-

Mounting plate can be used for inverters, chargers and all other equipment

-

Dust filters installed on inlet outlet vents

-

All-in-one design, store the leading brands of 19" rack mount type lithium batteries, inverters and controllers.

-

IP55 weatherproof, dustproof Robust construction

-

DC48V powered air conditioner, heat exchanger or TEC coolers are optional, which can cool down the devices installed inside the cabinet.

-

Battery Storage Space based on the battery specification.

-

Available in colours, Grey, Green or customized colors

Overview

An air-cooled C&I (Commercial and Industrial) Battery Energy Storage System (BESS) cabinet is a type of energy storage solution designed for commercial and industrial applications. It uses air cooling to manage the temperature of the battery cells, ensuring optimal performance, safety, and longevity.

Manufacturing an air-cooled Commercial and Industrial (C&I) Battery Energy Storage System (BESS) cabinet involves a combination of engineering, design, and assembly processes. Below is a step-by-step guide to help you understand the manufacturing process:

1. Design and Engineering

-

System Requirements:

-

Define the capacity, voltage, and power requirements based on the target application (e.g., peak shaving, backup power, renewable integration).

-

-

Thermal Management Design:

-

Design an efficient air-cooling system using fans, heat sinks, and ventilation to maintain optimal battery temperature.

-

-

Mechanical Design:

-

Create a robust and compact cabinet design using materials like steel or aluminum for durability and heat dissipation.

-

-

Electrical Design:

-

Plan the electrical layout, including battery modules, inverters, BMS (Battery Management System), and EMS (Energy Management System).

-

-

Safety Compliance:

-

Ensure the design meets industry standards (e.g., UL 9540, IEC 62619, NFPA 855).

-

2. Procurement of Components

-

Battery Cells:

-

Source high-quality lithium-ion cells (e.g., LFP or NMC) with the required energy density and cycle life.

-

-

Battery Management System (BMS):

-

Procure a reliable BMS to monitor and control cell voltage, temperature, and state of charge (SOC).

-

-

Cooling System:

-

Purchase fans, heat sinks, and ventilation components for air cooling.

-

-

Inverter/Converter:

-

Select an inverter suitable for the system's power rating and grid connectivity requirements.

-

-

Cabinet Enclosure:

-

Source or fabricate a durable, weather-resistant cabinet enclosure.

-

-

Wiring and Connectors:

-

Use high-quality cables, busbars, and connectors for efficient power transmission.

-

3. Assembly Process

Step 1: Battery Module Assembly

-

Arrange battery cells into modules, connecting them in series or parallel to achieve the desired voltage and capacity.

-

Integrate temperature sensors and wiring for BMS connectivity.

-

Secure the modules in a rigid frame to prevent movement and ensure safety.

Step 2: Cooling System Integration

-

Install fans and heat sinks in the cabinet to ensure proper airflow around the battery modules.

-

Design ventilation paths to allow hot air to escape and cool air to enter.

Step 3: Electrical Integration

-

Connect battery modules to the BMS and inverter using busbars and high-current cables.

-

Install the inverter, EMS, and other control systems inside the cabinet.

-

Ensure proper grounding and insulation to prevent electrical hazards.

Step 4: Safety Features

-

Install fire suppression systems (e.g., aerosol-based or gas-based extinguishers).

-

Add circuit breakers and fuses for overcurrent protection.

-

Implement thermal runaway detection and mitigation mechanisms.

Step 5: Enclosure Assembly

-

Mount all components securely inside the cabinet.

-

Seal the cabinet to protect against dust, moisture, and environmental factors.

-

Add access panels for maintenance and inspection.

4. Testing and Quality Assurance

-

Functional Testing:

-

Test the BMS, inverter, and cooling system to ensure proper operation.

-

-

Performance Testing:

-

Verify the system's capacity, efficiency, and thermal management under load conditions.

-

-

Safety Testing:

-

Conduct tests for overcharge, over-discharge, short-circuit, and thermal runaway scenarios.

-

-

Compliance Testing:

-

Ensure the system meets relevant industry standards and certifications.

-

5. Packaging and Shipping

-

Package the cabinet securely to prevent damage during transportation.

-

Include user manuals, installation guides, and safety instructions.

-

Label the cabinet with specifications, warnings, and compliance marks.

6. Installation and Commissioning

-

Provide on-site installation support to ensure proper setup and integration with the grid or renewable energy system.

-

Conduct final testing and commissioning to verify system performance.

Key Equipment and Tools

-

Battery cell stacking and welding machines.

-

Thermal management testing equipment.

-

Electrical testing tools (multimeters, oscilloscopes, etc.).

-

Safety testing equipment (e.g., thermal chambers, short-circuit testers).

-

Assembly tools (screwdrivers, wrenches, crimping tools).

Challenges and Considerations

-

Thermal Management: Ensure the air-cooling system is sufficient to handle heat generated during high-power operations.

-

Safety: Implement robust safety mechanisms to prevent fire or explosion risks.

-

Scalability: Design the system to allow easy expansion for future capacity increases.

-

Cost Optimization: Balance performance and cost by selecting high-quality yet cost-effective components.

Benefits of Air-Cooled C&I BESS

-

Cost-Effective:

-

Lower upfront and maintenance costs compared to liquid-cooled systems.

-

-

Energy Efficiency:

-

Reduces energy costs by storing excess energy during off-peak hours and discharging during peak demand.

-

-

Reliability:

-

Provides backup power during grid outages, ensuring business continuity.

-

-

Sustainability:

-

Supports renewable energy integration (e.g., solar or wind) and reduces carbon footprint.

-

-

Scalability:

-

Can be easily expanded to meet growing energy demands.

-

Applications

The Air-cooled C&I (Commercial and Industrial) Battery Energy Storage System (BESS) Cabinet is a versatile energy storage solution designed for a wide range of users across various industries. Below is a detailed breakdown of the key users and applications for this product:

1. Commercial Businesses

-

Office Buildings:

-

Reduce energy costs through peak shaving and load shifting.

-

Provide backup power during grid outages to ensure business continuity.

-

-

Retail Stores and Shopping Malls:

-

Lower electricity bills by optimizing energy usage during peak hours.

-

Enhance sustainability efforts by integrating renewable energy (e.g., solar panels).

-

-

Hotels and Hospitality:

-

Ensure uninterrupted power for guest comfort and safety.

-

Reduce operational costs by managing energy demand.

-

2. Industrial Facilities

-

Manufacturing Plants:

-

Stabilize energy supply for heavy machinery and production lines.

-

Reduce demand charges and energy costs by shifting load to off-peak hours.

-

-

Warehouses and Logistics Centers:

-

Optimize energy usage for lighting, HVAC, and automated systems.

-

Provide backup power for critical operations during outages.

-

-

Data Centers:

-

Ensure uninterrupted power supply to prevent data loss and downtime.

-

Reduce energy costs and improve energy efficiency.

-

3. Renewable Energy Projects

-

Solar Farms:

-

Store excess solar energy during the day for use at night or during cloudy periods.

-

Maximize the value of solar generation by avoiding curtailment.

-

-

Wind Farms:

-

Store wind energy during high-generation periods for use during low-wind conditions.

-

Smooth out fluctuations in wind energy output.

-

-

Hybrid Renewable Systems:

-

Combine solar, wind, and storage for a more reliable and consistent energy supply.

-

4. Utilities and Grid Operators

-

Peak Load Management:

-

Reduce grid stress during peak demand periods by discharging stored energy.

-

-

Frequency Regulation:

-

Provide grid stability by balancing supply and demand in real-time.

-

-

Microgrids:

-

Support the development of microgrids for remote or off-grid communities.

-

Enhance grid resilience and energy independence.

-

5. Agriculture and Farming

-

Irrigation Systems:

-

Provide reliable power for water pumps and irrigation systems.

-

Store solar energy for use during non-sunny periods.

-

-

Cold Storage Facilities:

-

Ensure uninterrupted power for refrigeration and cooling systems.

-

Reduce energy costs by optimizing energy usage.

-

6. Healthcare Facilities

-

Hospitals and Clinics:

-

Provide backup power for critical medical equipment and life-saving systems.

-

Reduce energy costs and improve energy efficiency.

-

-

Pharmaceutical Manufacturing:

-

Ensure uninterrupted power for sensitive manufacturing processes.

-

Optimize energy usage to reduce operational costs.

-

7. Educational Institutions

-

Schools and Universities:

-

Reduce energy costs by managing peak demand and integrating renewables.

-

Provide backup power for classrooms, labs, and administrative offices.

-

-

Research Facilities:

-

Ensure reliable power for sensitive experiments and equipment.

-

Support sustainability initiatives with renewable energy integration.

-

8. Telecommunications

-

Cell Towers and Data Centers:

-

Provide backup power to ensure uninterrupted communication services.

-

Reduce energy costs by optimizing energy usage and integrating renewables.

-

9. Remote and Off-Grid Locations

-

Mining Operations:

-

Provide reliable power for remote mining sites.

-

Reduce reliance on diesel generators and lower fuel costs.

-

-

Island Communities:

-

Support microgrids for energy independence and resilience.

-

Store renewable energy for use during non-generation periods.

-

10. Transportation and EV Charging

-

Electric Vehicle (EV) Charging Stations:

-

Store energy to support fast charging during peak demand.

-

Reduce grid impact and lower energy costs.

-

-

Public Transit Systems:

-

Provide backup power for electric buses, trains, and trams.

-

Optimize energy usage for transit operations.

-

11. Government and Municipalities

-

Public Buildings:

-

Reduce energy costs for government offices, libraries, and community centers.

-

Provide backup power for emergency services.

-

-

Street Lighting:

-

Store solar energy to power streetlights at night.

-

Reduce grid dependency and energy costs.

-

12. Event Venues and Stadiums

-

Concert Halls and Arenas:

-

Provide backup power for events and ensure uninterrupted operations.

-

Reduce energy costs by managing peak demand.

-

-

Outdoor Events:

-

Support temporary power needs for festivals, fairs, and exhibitions.

-

Summary of Key Users

| Sector | Primary Use Case |

|---|---|

| Commercial | Peak shaving, backup power, sustainability. |

| Industrial | Load shifting, energy cost reduction, process stability. |

| Renewable Energy | Solar/wind integration, energy storage, grid stability. |

| Utilities | Peak load management, frequency regulation, microgrids. |

| Agriculture | Irrigation, cold storage, renewable energy integration. |

| Healthcare | Backup power for critical systems, energy cost reduction. |

| Education | Energy cost savings, backup power, sustainability. |

| Telecommunications | Backup power for cell towers, energy optimization. |

| Remote Locations | Energy independence, reduced reliance on diesel generators. |

| Transportation | EV charging support, backup power for public transit. |

| Government | Energy cost reduction, backup power for public services. |

| Event Venues | Backup power, temporary energy solutions. |

Why They Need It

-

Cost Savings: Reduces energy bills and demand charges.

-

Energy Resilience: Provides backup power during outages.

-

Sustainability: Supports renewable energy integration and reduces carbon footprint.

-

Operational Efficiency: Optimizes energy usage and improves grid stability.

This product is ideal for any business or organization looking to reduce energy costs, improve sustainability, and ensure reliable power supply. Let me know if you'd like to dive deeper into any specific sector or use case!

Specification

| Environmental | |

| IP (Ingress Protection) Rating | IP55,NEMA 4,NEMA 4X |

| Working Temperature | -40~55℃ |

| Physical | |

| Color | GREY RAL7035 |

| Material | Galvanized steel(Aluminum/stainless steel/Color coated steel optional) |

| Unit Dimensions (WxDxH) | 25.6inches x 24inches x 40.23inches |

| Unit Weight | 160lbs. |

| Shipping Dimensions(WxDxH) | 27.6inches x 26inches x 48.23inches |

| Shipping Weight | 200lbs. |

| Weight Capacity (static load) | 800lbs. |

| Electronics | |

| Cooling | Cabinet Air Conditioner (Heat Exchanger/Thermoelectric Cooler(TEC) Optional) |

| Heating | As optional |

| Fans | DC48V |

| Power | PDU(Basic or Smart),AC/DC Power,Built-in Power Optional |

| Sensors | Door Sensor/Water Sensor/Temperature & Humidity sensor/Smoke sensor/Tilt & Shock sensor |

| Monitoring | EMS,KVM Switches,Smart PDU |

| Certifications | |

| Approvals | EIA/ECA-310-E, IEC 294-2, RoHS |

| Safety | CE |

| Warranty | |

| Standard warranty | 1 Year |

How to Order

Our Air-Cooled C&I BESS features an integrated design that combines the PCS and battery into a single cabinet. This product is highly flexible and expandable to meet the diverse application needs of various clients.To ensure reliability and stability, the battery system uses a air cooling system to maintain optimal operating temperatures, thereby enhancing the performance and lifespan of the storage system.

Key Features of Air-Cooled C&I BESS Cabinets

-

Air Cooling System:

-

Utilizes fans or natural convection to dissipate heat generated by the battery cells during charging and discharging.

-

Simpler and more cost-effective compared to liquid cooling systems.

-

-

Modular Design:

-

Compact and modular cabinets allow for easy installation, scalability, and maintenance.

-

Can be customized to meet specific energy storage requirements.

-

-

Battery Chemistry:

-

Typically uses lithium-ion batteries (e.g., LFP - Lithium Iron Phosphate) due to their high energy density, long cycle life, and safety.

-

-

Integrated Management Systems:

-

Equipped with a Battery Management System (BMS) to monitor cell voltage, temperature, and state of charge (SOC).

-

Energy Management System (EMS) for optimizing energy usage and grid interaction.

-

-

Safety Features:

-

Includes fire suppression systems, thermal runaway prevention, and fault detection mechanisms.

-

Complies with industry safety standards (e.g., UL, IEC, etc.).

-

-

Grid Connectivity:

-

Supports grid-tied or off-grid applications.

-

Enables peak shaving, load shifting, and backup power.

-

**********Notes**********

-

Shipping Option: Assembly unit with carton or wood pallet

-

Waterproof outdoor electrical enclosures IP Rating: IP55,IP65 rated or NEMA 3R,NEMA 4, NEMA 4X rated available

-

Outdoor Enclosures Material Options: SPCC Cold Steel, Galvanized steel, Stainless steel or Aluminum available.

-

Outdoor Telecom Cabinet Cooling options: such as cooling fans, Cabinet air conditioner , Plate heat exchanger and Thermoelectric cooler available.

|

No.

|

Item

|

Specifications

|

|

1

|

AC110V or 220V/DC48V, Cooling Capacity 300W-5000W

|

|

|

2

|

DC48V, Heat transfer 40W/K-200W/K

|

|

|

3

|

DC48V, Cooling capacity 100W-300W

|

|

|

4

|

Fan

|

AC110/220V or DC 48V

|

-

A wide range of server rack accessories ,Fiber optics cabling solutions,Server Rack PDUs and KVM solutions compatablity

-

Grey(RAL7035) or other customize colors available

-

Outdoor telecom enclosure optional accessory parts

|

No.

|

Item

|

Specifications

|

|

1

|

Fan

|

AC110/220V or DC 48V

|

|

2

|

Power Supply

|

AC INPUT: 32A/1P MCB or 63A/2P MCB

DC OUTPUT: 16A/1P MCB |

|

3

|

Environment Monitoring Unit

|

48VDC Communication port: RS485, TCP/IP, SNMP optional

|

|

4

|

Door Sensor

|

Monitor door open status inside cabinet and provide real time alarm.

|

|

5

|

Water Sensor

|

Monitor water status inside cabinet and provide real time alarm.

|

|

6

|

Tilt & Shock Sensor

|

Monitor shock status inside cabinet and provide real time alarm.

|

|

7

|

Temperature & Humidity Sensor

|

Monitor temperature and humidity inside cabinet and provide real time alarm.

|

|

8

|

Smoke Sensor

|

Monitor smoke status inside cabinet and provide real time alarm.

|

Outdoor Battery Cabinet Enclosures can be customized for all Outside Plant applications - special engineering and additional equipment integration also available. Additional cabinet sizes are available. Call us or email us for information and pricing.

GET A QUOTE

While we strive to create custom products, please note that not all requests will qualify for a free prototype. Determination will depend on your project needs, quantity, and a final management review.

Let's get started, we are ready to work with you! Fill out the information below to send in your request and requirements and our team will be in touch shortly.